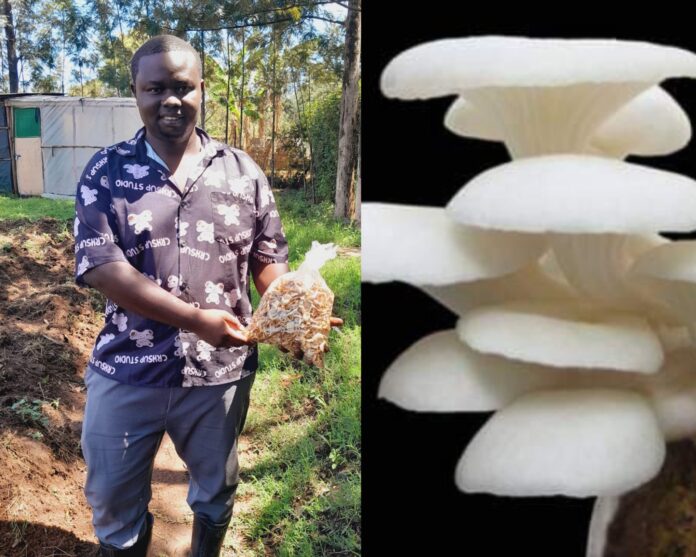

At Kajulu Farms, Juma Sylvester spearheads a quiet agricultural revolution through his innovative mushroom production agribusiness.

With a primary focus on Oyster mushroom, one of the most adaptable varieties, Sylvester’s venture showcases the potential of indoor farming and sustainable practices.

Oyster mushrooms are an edible type of fungi, typically light grey or brown and can come in different colours including yellow and pink.

A report by National Farmers Information Service survey shows that Kenya produces approximately 500 tonnes of mushrooms annually against the demand of 1200 tonnes.

According to Fredrick Omondi, a mushroom production expert and research specialist, oysters are some of the easiest types to grow due to their fast growth, wide variety of potential and tolerance to growing conditions (GroCycle publication).

Unlike traditional farming, Oyster mushroom production at Kajulu Farms is done indoors in meticulously controlled environment and temperatures.

This variety is one of the most versatile mushrooms in the world and can acclimate to any form of climate or temperature. There are other forms like button, shiitake, which they are yet to introduce.

In an interview with Lake Region Bulletin, Sylvester shared the intricacies of mushroom cultivation, shedding light on the processes involved in turning waste into profit.

Unlike traditional farming, Oyster mushroom production at Kajulu Farms is done indoors in meticulously controlled environment and temperatures.

Sylvester and his team have designed specialized structures for different stages involved in the production and mushroom growth: nursery, for incubation and the production room where mushroom grow out and eventually mature for harvest.

This production is not done on the soil rather in a more controlled design such as paper bags or cartons because of the substrate used to form the base.

A mixture of organic waste materials like maize cobs, dry banana leaves, sugarcane bagasse, rice straw, hyacinth and saw dust are oftenly used as substrate.

This unique approach of recycling not only helps to utilize excess products that would otherwise pollute the environment but also significantly reduces production costs.

Where it all began

Sylvester’s journey from a law graduate to a mushroom farming pioneer is a testament to resilience and adaptability.

In 2020, When Covid-19 hit Kenya and things went south, he had to find something to do.

Sylvester had seen a friend in Limuru do mushroom production and picked an interest into it.

He hooked up with him and got the basic skills and practical trainings to offer the hands-on skills. Sylvester has since then undertaken mushroom production courses and researches to enable him even train other into the production.

His story stands as a beacon of hope showcasing the transformative power of innovation, sustainability and community empowerment in agriculture and a potential of mindful agricultural practices.

The production of mushrooms involves a well-choreographed process of care and innovation. After a series of treatments, the waste materials used as substrate serve as the nourishing base for mushrooms.

Using metallic tanks, the substrate is socked in water to dissolve it’s nature, and soften it for the bags. This usually takes 42hours to 72hours.

The product is then sun dried for a while of upto 6 hours to drain the water from the substrate and a supplement introduced inform of manures.

“The product is then packaged to the brim to make sure it’s a block, because organically, mushrooms thrive in moist blocks. At this stage, the blocks are of 5kg and 2.5kg bags where the smaller ones are easier to maintain,” notes Sylvester.

The block is tied with a rope to ensure there is no air coming out.

The package therefore has to be sterilized, since mushroom is a fungus competing other fungi that can affect it and result to molds which then greatly affect the yields.

Dealing with competition with other fungi

“We then subject the block to very high heat of over 120 degrees Celsius at a time for more than four hours using tanks (the bags are put inside the tank, cover the bags with blanket, pour water inside then subject to heat),” he says.

The steam produced sterilizes the bags in order to make the fungi(mushroom) more competitive, not be affected by other fungi.

The bags are then removed and cooled down for an hour or two.

At this point, they introduce a mushroom spawn into the carefully sterilized substrate, triggering the growth process. During the process, the environment and those handling it must be sterilized to reduce contamination.

The amount of mushroom spawn introduced will depend on the size of the bag.

The bags are then loosely tied to allow air in, to aerate the substrate and in turn multiply the mycelium mechanism so to spread more robustly.

According to Sylvester, the seeds are put in the substrate because the mycelia that grows into mushroom likes feeding on organic waste. So once spawned, it feeds on them to its brink.

The incubation room has to be very dark and quite hot about 28degrees Celsius to aid mycelia which likes to grow/camouflage in dark places.

Depending on the quality of the spawn used and quality of the organic waste, it may take 14 to 30 days.

Once done, the product turns white meaning that the seeds have taken over all the substrate used, and all the nutrients. This works as a web, signaling that the incubation part of it is concluded and it can be moved to the second stage.

In the production room, light and cold temperature target at 22degrees Celsius going down is maintained. Grass, mud thatched houses and black paper are used. The level of aeration in the room should be at least 17 per cent to provide optimum growth of the mushroom.

Sylvester says they do spray water on the floor, wall and bags to maintain the moist temperature.

The bags are opened (which takes two to seven days) and under these controlled conditions, the mushrooms thrive, transforming waste into a valuable commodity.

After the three months, the bags are used as organic manure in the farms. The bag may also be subjected into heat and made into padded blocks which may be used as building materials to make roofs and walls.

Secrets to dealing with infections

Sylvester emphasizes the importance of sterilization to combat other competing fungi. He uses high heat in the incubation stage to ensure the mushrooms remain unaffected to achieve quality and consistency.

At the doors of the mushroom houses, there is a footbath that is used to sterilize and discourage mold contamination.

Pest control is as much vital. Innovative methods like sweet-smelling brightly-coloured stickers deterring flies are used.

There is no need of using organic waste that is so expensive thereby increasing the cost of production

Sylvester

Basically, the waste materials used such as sugarcane bagasse (which has sucrose) is readily available from Kibos Sugar factory. Dry banana peels, leaves and hardwood saw dust are as well locally available. This eases the cost of production.

“There is no need of using organic waste that is so expensive thereby increasing the cost of production,” Sylvester says.

Each 2.5kg bag produces mushrooms for three months, generating substantial profits and promoting sustainability.

Each bag will give about 500 grams of mushroom which is approximately 500 shillings. The harvest and purchase are done in cycles.

The demand for production is very high, the mushroom can be sold while fresh or dry. The fresh one lasts up to two days without refrigeration and 4days under refrigeration. Most of the sales are done in dry form.

The main market is to wholesalers who do value addition, where it is used to bake and make floor.

While fresh, 250grams goes for 250 shilling while the dry ones, a kilo goes for 3000 shillings. Yearly the production can hit 50-60 kilograms and even more in large scale farming.

Beyond Profit: Mushrooms impact on health and community

The benefits of Oyster mushroom go far beyond financial gains. They have nutritional value and a role in production of mushroom wine, crisps and nutritious porridge.

Additionally it has been linked to treating various health conditions, from high blood pressure to diabetes, making them a valuable addition to the local diet.

Oyster mushrooms include beta-glucan which helps reduce cholesterol levels in the blood while supporting heart health as medically reviewed by Marisa Moore, a registered dietitian nutritionist.

They also contain vitamin B which helps the digestive system and red blood cells function better.